Torch down roofing is used on flat or low sloped roofs.

Torch down vs roll roofing.

Torch down roofing mineral surface rolled roofing roll roofing low slope roll roofing roll roofing roofing materials.

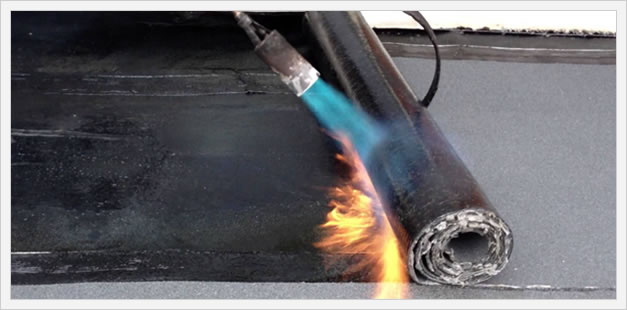

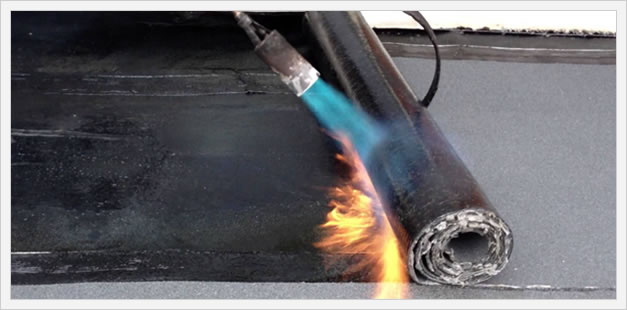

As the name implies it involves the use of a blowtorch to melt a petroleum based substance called bitumen to creat.

How doers get more done.

Torch down systems involve heating the adhesive as the material is unrolled.

There are two main types of torch down roll roofing.

Peel and stick material can be installed by homeowners.

The other half say that torch down is the wrong way to go because the seams or top layer begin to crack within 5 years and the application can be dangerous if not done properly i e.

While it can last up to 20 years installing torch down roofing can be a dangerous process and as such tends to cost more than traditional roofing materials.

To install torch down roofing roofers roll out sheets of a bitumen containing material.

Two layer systems and three layer systems.

Watch this video if you want to learn how to use a propane torch on a flat roof.

Newer peel and stick systems are safer and easier.

Owens corning deckseal sa sbs cap 39 375 ft w x 32 833 ft l 100 sq ft shasta white roll roofing.

Both systems have a base and cap sheet but in the three layer system the roofing professional will apply a base sheet then a smooth cap sheet and finish with a granule cap sheet.

This membrane contains a core of nonwoven polyester mat that resists splits and tears.

Torch down roofing is a type of roofing material that has been designed for low angle or flat roofs.

A single ply rolled roof similar to ice and water shield but impregnated with a mineral based wear surface.

This will help you get started and you will also learn some tricks.

This extra layer helps extend the life of the roof and usually.

These guys instead are proposing using a cold process with a slightly thinner material typically tamko awaplan rubberized roll with elastomeric adhesive.